Expertise, Quality, Guaranteed Performance

Nordstrong Equipment Limited’s industrial bucket elevators are the “gold standard” for several large multinational companies. Our reputation for dependable purpose built chain and belt bucket elevators is why they rely on Nordstrong for their elevating needs. The design of Nordstrong Equipment Limited’s industrial bucket elevators includes a variety of design parameters such as, bucket profile, material handled, material density, design capacity and service factor.

To achieve the best in material handling we offer the characteristic design features of “Centrifugal” and “Continuous” style elevators for specific applications, along with our empirical design knowledge.

Industrial Centrifugal Type

Recommended for handling relatively fine free-flowing and loose bulk materials with small to medium sized lumps. Material is discharged by centrifugal action as the interval spaced buckets pass over the head wheel.

Loading is accomplished by directly feeding material into the buckets at the inlet.

Belts are preferred for more abrasive applications, provided high temperatures are not a factor.

Continuous Type

The continuous discharge elevator is used to handle sluggish, aerated material or product having a large percentage of lumps. Mounted continuously on either belt or chain and operating at much slower speeds, the buckets form a chute as they pass around the sprocket or pulley. Gravity causes the material to fall gently onto the back of the preceding bucket and out of the discharge spout.

Heavy Mill Duty Industrial Elevators

First designed and commonly known as “Cement Mills”, these elevators meet the most severe bulk material handling requirements. Now used for a variety of high capacity and abrasive applications, their design and durable construction make them ideal candidates for the toughest environmental conditions.

Usually mounted on a single strand of steel bushed chain, AC or SAC buckets travel at speeds high enough for a clean centrifugal discharge.

SJ Type

Developed as an alternative to meet the needs of today’s industrial type elevators, particularly cement, this high performance heavy guage pressed seamless steel bucket is designed and engineered to replace large fabricated buckets. Compared to traditional chain and bucket formats it offers substantial increases in capacity relative to the casing size of conventional elevators. Capable of running at speeds up to 430 F.P.M. with throughput in excess of 1000 T.P.H., it is ideally suited for high capacity/high lift applications and provides unequalled opportunity to upgrade existing equipment. Also available with reinforced wear lip, it is closely mounted on standard rubber or steel-web belt for ultimate performance.

Supercapacity style elevators are more suited to handling friable, heavy or abrasive materials at very high capacity and can accommodate very large lumps. The massive ‘H’ style buckets are end-mounted continuously between two strands of high quality steel bushed roller chain.

Material is fed to the buckets through an internal loading chute. Extremely low speeds guarantee true continuous discharge and ensure long-life.

For assistance in determining the correct equipment for your needs, please contact a Nordstrong technical sales representative for your next project.

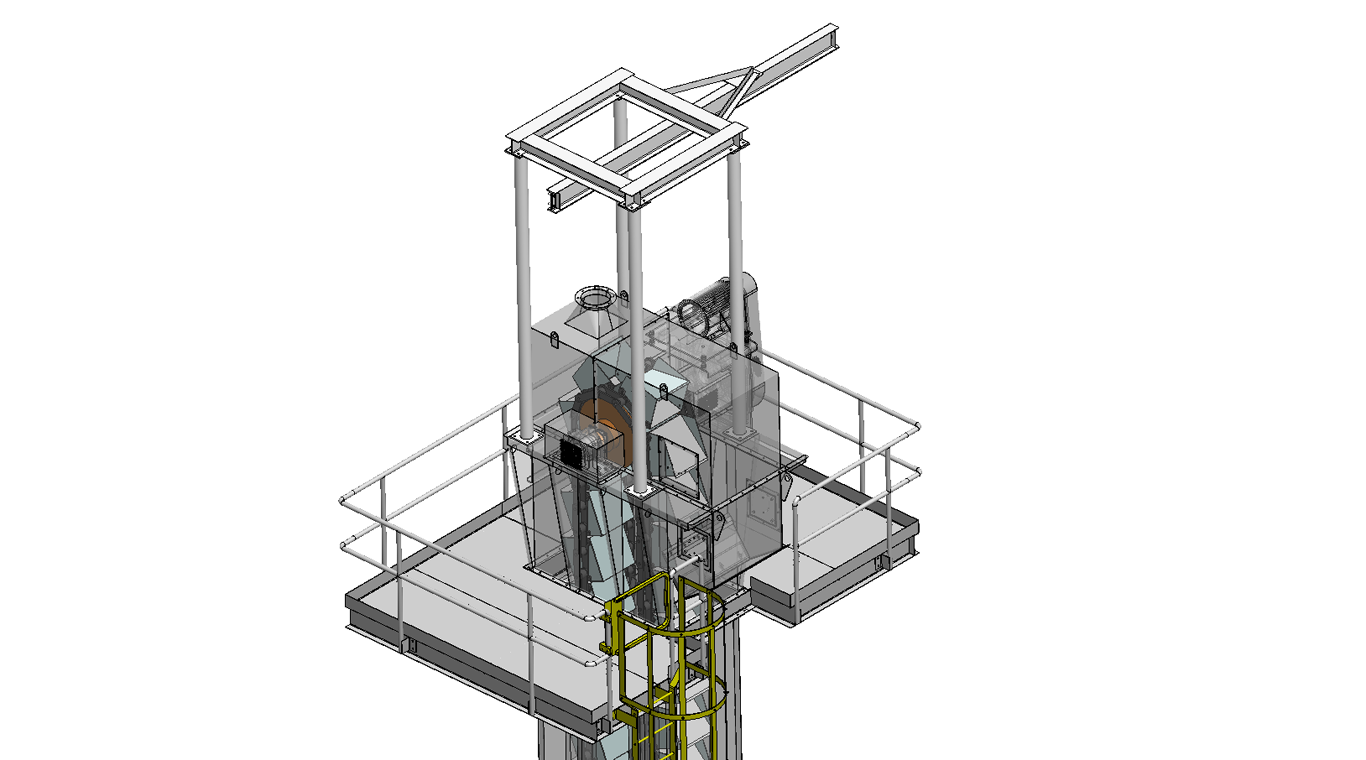

Head Section

- Factory assembled

- Roller bearing pillow blocks

- Adjustable bearing pedestals

- Weather tight inspection doors with re greasable hinges

- Adjustable throat baffle

- Split hood with shaft seals

- Crown faced double disc drum pulley with vulcanized lagging or hardened tooth sprocket

- Optional split, segmented sprocket or traction wheel

Boot Section

- Factory assembled

- Externally mounted flange or pillow block bearings

- Acme screw take-up with shaft seals

- Optional gravity take-up with internal hard iron bearings (available with stellite sleeves)

- Hinged and bolted access panels

- Boot inlet

- Crown faced double disc drum or wing pulley, or matching sprocket/traction wheel combination

Casing

- Heavy gauge construction to suit any application

- Jig welded with continuous seams and structural angle iron flanges

- Oversize hinged and bolted inspection doors

Drives

- Standard or customer specified drives for all models

- OSHA guards

Optional Features and Accessories

- Stainless steel construction

- Special paints

- Head take-ups

- Special designs for various environmental conditions

- Explosion Vents (NFPA 61, 68)

- Custom inspection maintenance doors

Liners

- U.H.M.W. or urethane

- Abrasion resistant liners

- Overlay plate

Ladders and Platforms

- Standard or custom platforms

- Step off, rest and valve service platforms

- Bolted or welded OSHA. caged ladders