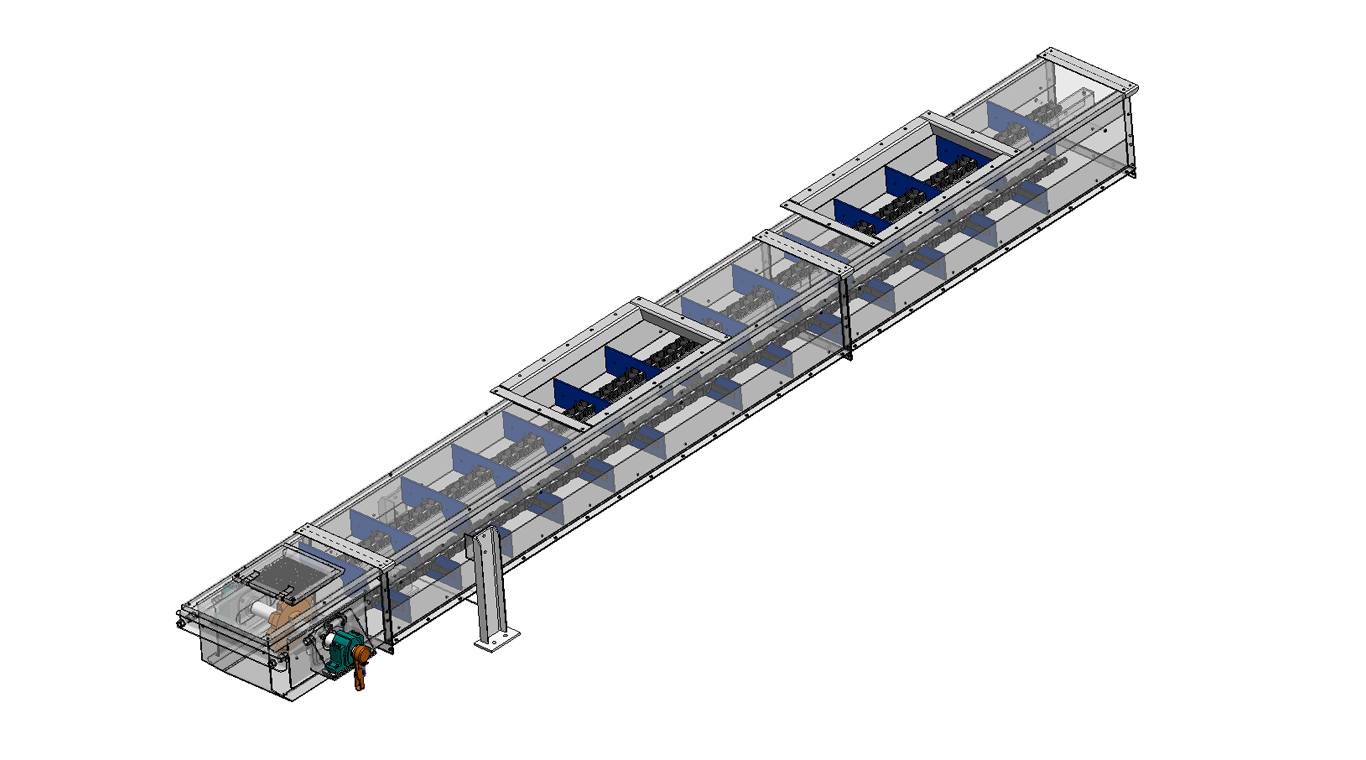

High Performance, Quiet Operation, Reliable

Nordstrong's agricultural conveyors use the en-masse principal of conveying to achieve compact design. They are available in a wide range of standard sizes and configurations that are typical of industry standards to suit your requirements. Capacities ranging from 3000 to 53920 BPH.

For assistance in determining the correct equipment for your needs, please contact a Nordstrong technical sales representative for your next project.

Head Section

- Standard heavy gauge fully bolted box head section

- Sprocket with hardened teeth

- Optional split sprocket (Standard on HDC Series)

- Optional outboard mounted pillow block bearings utilize U.H.M.W. seals (Standard on HDC Series)

Drives

- Standard or customer specified drive packages available for all models

- Shaft mount with belt drive

- Gear motor with chain and sprockets

- Direct coupled combinations

- OSHA guards

Covers

- Weather tight covers on head, tail and intermediate sections - optional hip roof available

- Standard galvanized ‘C’ type clamping system

- Optional quick release cover clamps

- Galvanized cover joints

Intermediate Trough Section

- Troughs are available in several designs. Gauge of steel used in construction varies depending on model and application

- All trough styles are available with full height A.R. steel side liners for severe duty applications and continuous service

- All troughs are jig welded with heavy flat bar or angle flanges

Discharge Gates

- In-line gates

- Drop bottom gates

- Cross gates

- Flush mount gates

- All available with a variety of operators: Manual, Electric Gear motor, Electric (linear) Actuator, Hydraulic or Pneumatic

Chain

- Chain style selected to suit individual application

- Welded steel flight attachments

- Full width U.H.M.W. bolted flights

Tail Section

- The Nordstrong Tail Detector Device (standard on all models) provides for automatic chain tensioning, for longer life and complete chain protection.

- If chain tension is lost due to the presence of foreign objects, the Detector Device shuts off the conveyor before damage occurs.

- Flange or pillow block bearings

- Sprocket with hardened teeth

- Optional split sprocket (standard on HDC Series)

- Take-up adjustment provided with corrosion resistant ACME threaded rod

- Optional outboard mounted pillow block bearings utilize U.H.M.W. seals (Standard on HDC Series)

- Tail detector

Inlets

- Standard raised or flanged

- Optional metered feed or bypass (divided flow)