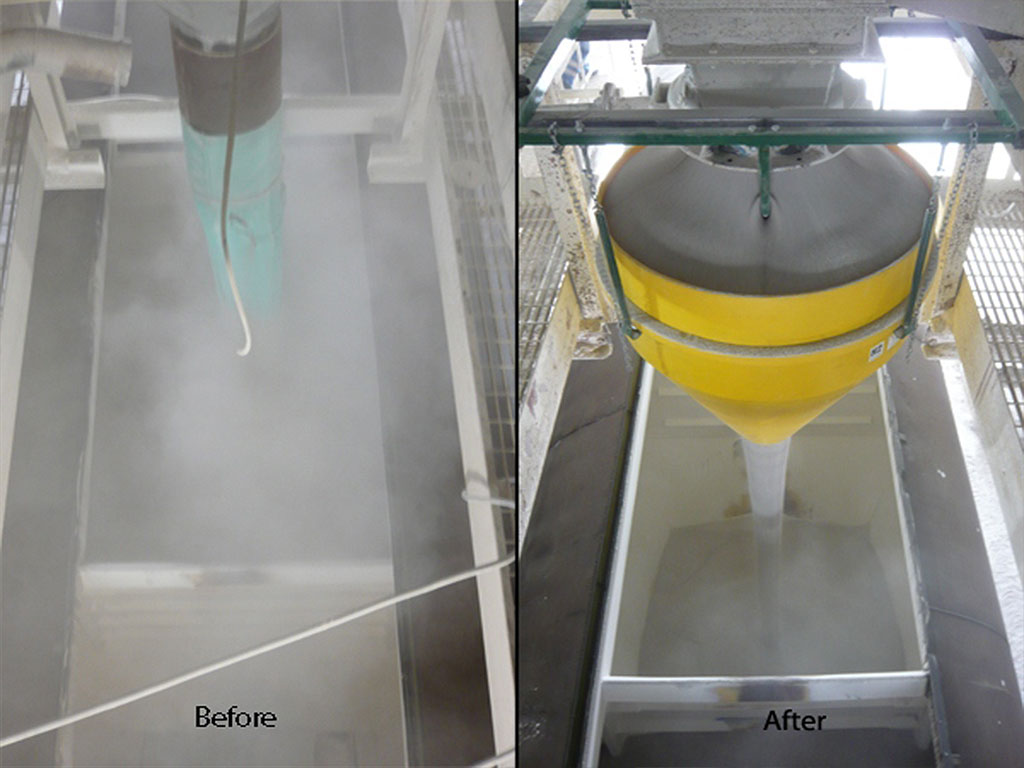

Ideal for a range of applications including dockside loading, the award winning Dust Suppression Hopper is highly effective, following years of fine tuning and development work, so it’s no surprise that companies around the world are eager to reap the benefits of this internationally tested and superior system. Extensive research proves the DSH works well on many different dry, free-flowing granular products.

This award winning Dust-Free Loading Spout ingeniously contains the dust within the product stream when discharging dry bulk materials. Thus, it cleverly avoids the need for the more complicated retractable loading spouts or telescopic loading spouts that are more commonly used in today’s truck loading and outloading applications.

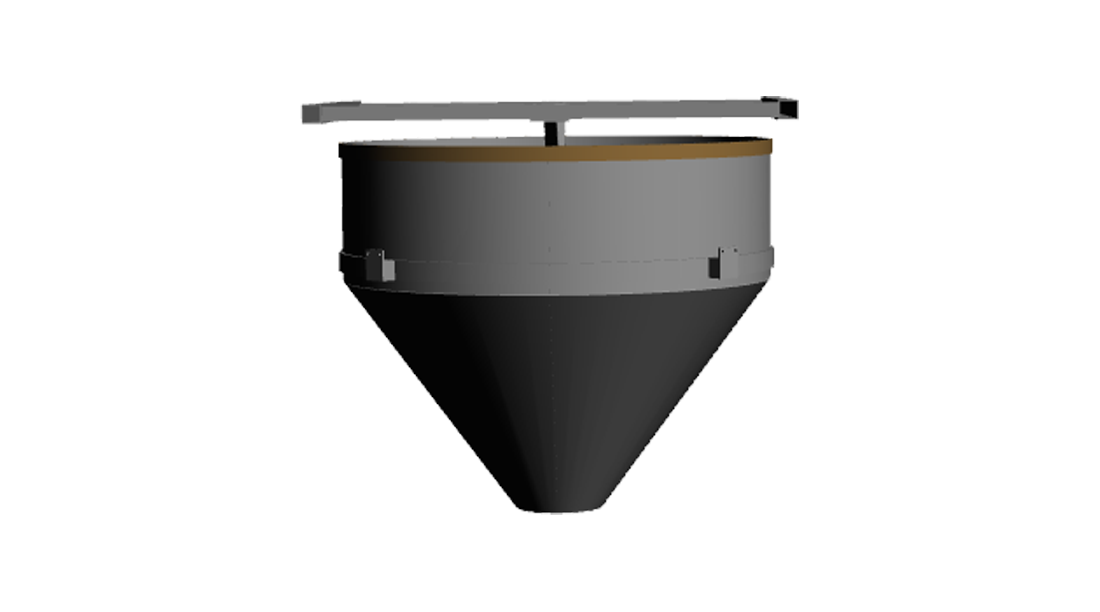

Specification

The DSH (loading spout) is installed under a feed point where it can be suspended above the target and kept at operating level. A small degree of natural agitation as the loading hopper is filled helps exclude air from the material being transferred. At the point of loading, the DSH concentrates the discharge of dry goods as a solid column through free air into any target repository including trucks, rail cars, stock piles, storage containers or bags. Previously, trucks taking on a load simply disappeared in a dust cloud.

Uncomplicated to install and easy to operate and maintain, the DSH dust suppression loading spout reduces hazards, health risks, dust, wastage, cleaning and maintenance costs and increases storage capacity.

Standard Features and Options

DSH Systems produce polyethylene rotational moulded loading hoppers to cover most applications, Carbon steel and 304 stainless steel loading hoppers for warm or abrasive products and 316 stainless steel loading hoppers for food grade applications. These models require no power.

DSH Systems produce polyethylene rotational moulded loading hoppers to cover most applications, Carbon steel and 304 stainless steel loading hoppers for warm or abrasive products and 316 stainless steel loading hoppers for food grade applications. These models require no power.

DSH Systems Ltd The more advanced PFC model (Positional Feed Control) has a computerised discharge rate control system for products with different specific gravities; thus allowing the load-out of a range of different materials from the same conveyor system.

There are currently 11 models in the range. Hopper size selection depends on product bulk density and loading rate per hour.

Learn more about DSH.