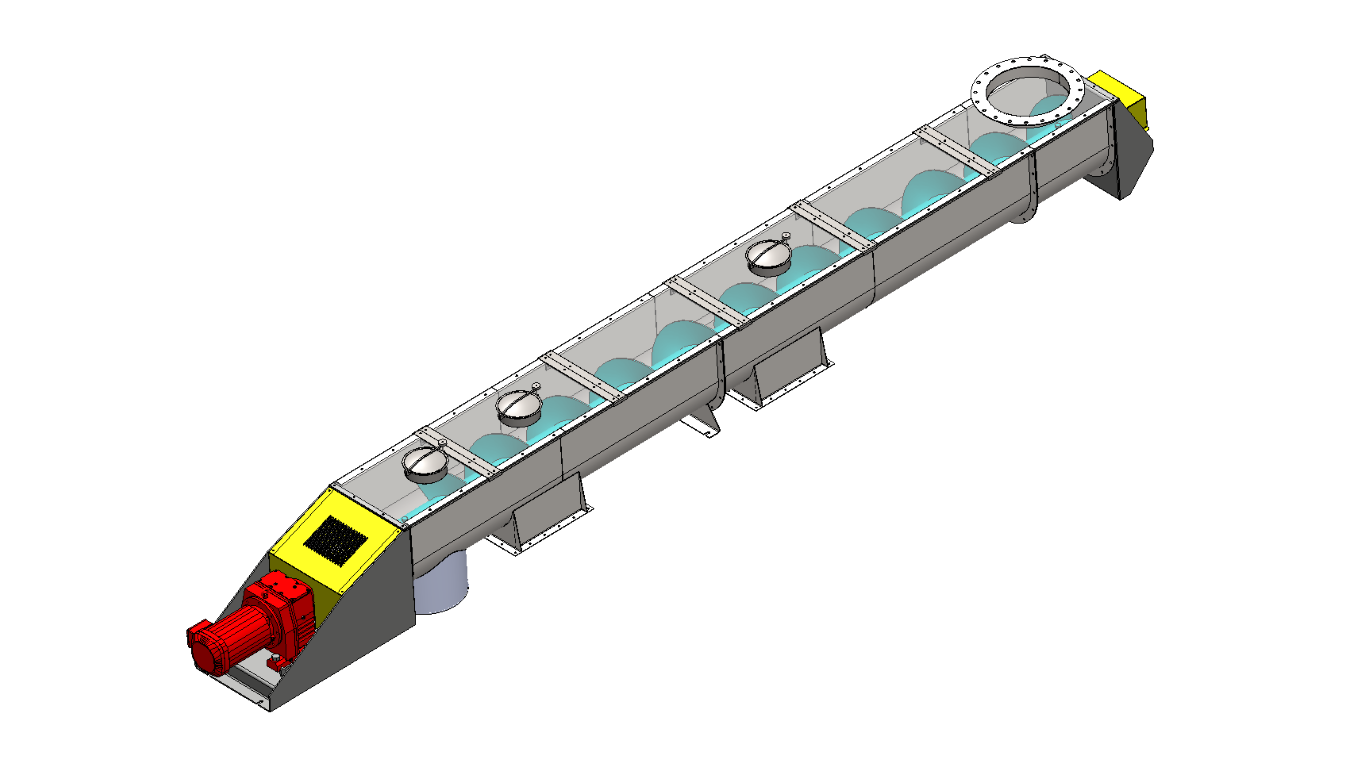

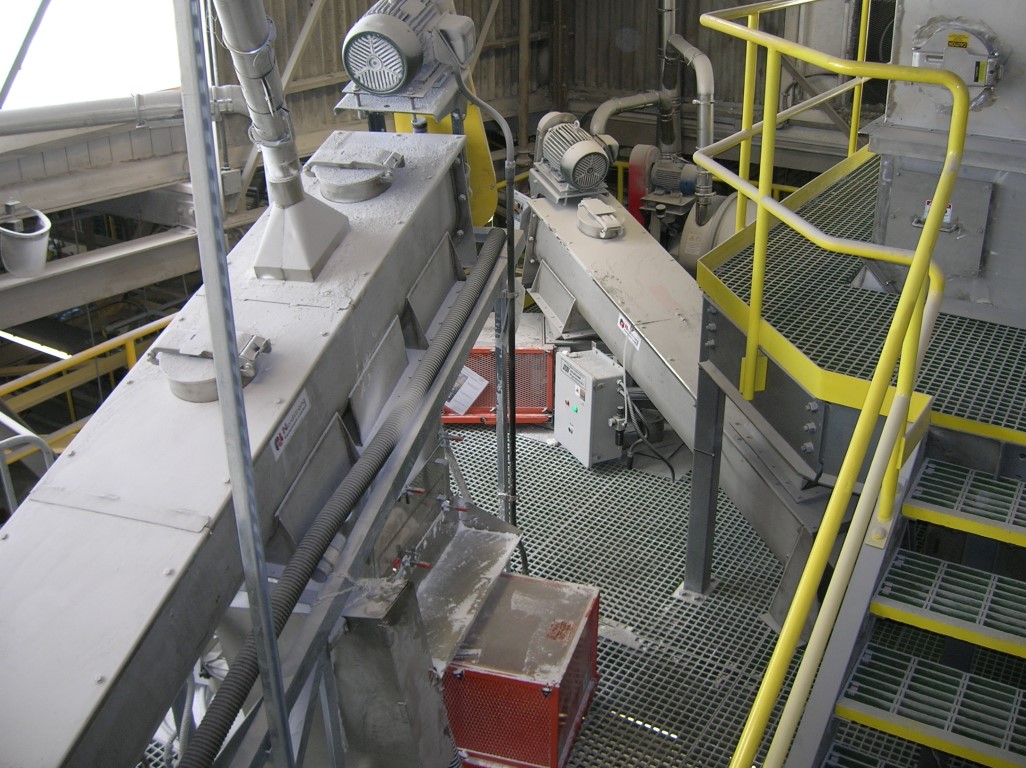

Nordstrong Equipment Limited offers the most comprehensive line of screw conveyor assemblies and components available anywhere. With over 100 years’ experience in the principles, practices and challenges of handling a wide variety of materials, we design and manufacture your conveyors to meet specific design parameters and applications. Screw Conveyors have been used throughout the world for moving product in numerous industries and under an extensive range of operating conditions.

Archimedes principle was simple, however in today’s market its application can be a challenge. We can fabricate from an extensive range of materials (mild steel, stainless steels, abrasion resistant plates, hard surfacing materials and ceramic coatings). Please use the information provided as a guide only as many alternatives are available.

For assistance in determining the correct equipment for your needs, please contact a Nordstrong technical sales representative for your next project.

Design

Nordstrong screw conveyors are designed and classified according to Conveying Equipment Manufacturers Association (C.E.M.A.) standards for each individual application.

Conveyor Screws

- Helicoid or sectional flights

- Short, variable and long pitch

- Cut or cut and folded

- Mixing paddles and paddle conveyors

- Tapered diameter or cone design

- Single or multiple ribbon

- Double helix

Trough

- Troughs are available in several designs. Gauge of steel used in construction varies depending on size of conveyor and application

- Jig welded with heavy flanges

- Formed or angle flanged ‘U’ trough

- Solid or split tubular construction

- Flared designs

Covers

- Covers are also available in several designs

- Weather tight gasketed construction

- Flat or flanged with butt strap

- Hip roof available

- Hinged designs

- Bolted or clamp type fasteners

- Quick release clamps

Bearings and Seals

- Flange or pillow block

- Ball, roller and heavy duty thrust bearings

- Packing and plate seal housings

- Packed and split gland seals

- High temperature bearings and seals available

Drives

- Standard or customer specified drives available for all sizes

- Screw conveyor or shaft mount; with belt drive

- Gear motor with chain and sprockets

- Direct coupled combinations

Optional Features

- Special Models

- Inclined

- Reversing

- Mixing and blending

- Wear shoes

- Custom designs

Hangers and Shafts

- Conventional or expansion types

- Non ferrous or hardened materials

- Lubrication tubes and ball bearing options

- Multiple hole shaft drilling

- External sleeves

- Quick release ends

- Flanged coupling shafts

Inlets and Discharges

- Standard or custom inlets

- Optional feeder (shroud) designs

- Stub or flush end discharges

- Hanger end and special outlets available

Gates

- Flat slide or curved gates

- Drop bottom gates

- Dust tight designs

- All available with a selection of operators: manual, electric gear motor, electric (linear) actuator, hydraulic or pneumatic

Construction Options

- AR Plate construction

- Hard facing

- Stainless steel

- Feed, food and sanitary finishes

- Galvanized

- Epoxy paints

Safety

- Plug switches

- Overflow relief doors

- Under speed detection

- Pressure relief vents